Counterfeit-part risk mitigation begins with avoidance as Bostock diligently selects, qualifies, and continuously evaluates suppliers, ensuring their adherence to ISO 9001:2015 certification standards and their capability to meet customer requirements.

SOURCING

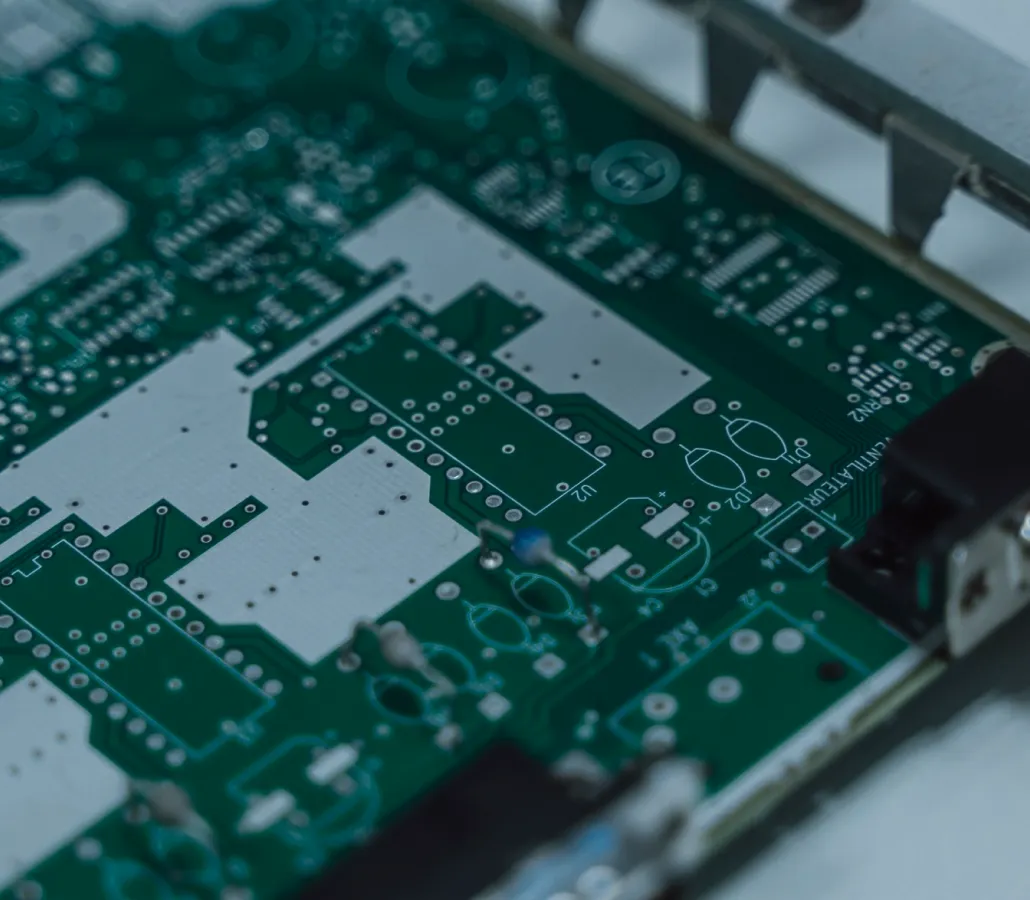

Bostock's dedicated quality inspectors conduct meticulous examinations of components, carefully verifying part dimensions, markings, leads, packaging, and other characteristics to ensure strict compliance with manufacturer specifications.

Visual Inspection Capabilities

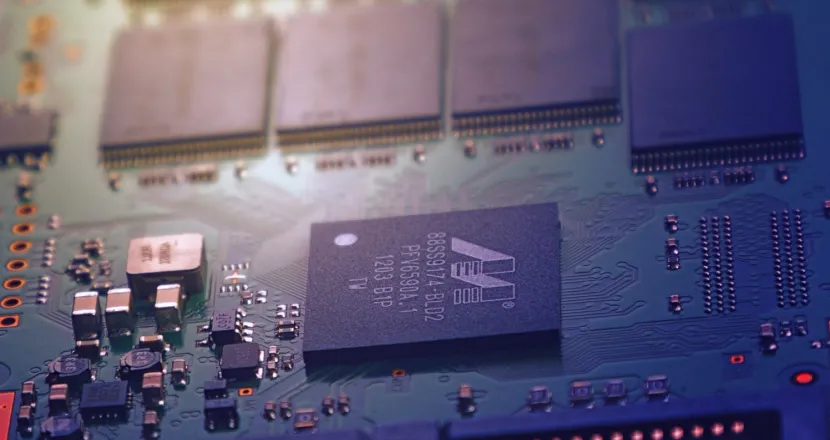

Nondestructive Testing

Non-destructive testing encompasses various inspection techniques that enable inspectors to gather data about a material without causing any damage to it.

These methods are instrumental in detecting defects, identifying imperfections, and pinpointing their locations on the material's surface.

Nondestructive Testing Capabilities

03

Destructive Testing

Destructive testing is typically carried out before a component enters mass production, involving processes like decapsulation and lead solderability, to precisely identify the point of failure in materials, components, or machines. This ensures the highest level of quality and reliability in the final product.

Destructive Testing Capabilities

Custom Testing

Bostock takes pride in tailoring authenticity testing services to match our clients' specific requirements, and we are eager to share more details upon request. Don't hesitate to contact us today for further information on Bostock's authenticity-testing services.